With the help of the glutomatic system from the Perten company, a dough is made and subsequently all the soluble components washed out of the dough in one wash. Here, the starch and the non-gluten-forming proteins are removed to isolate the gluten-forming proteins.

For this, a dough is made in the mixing chamber of the device from 10 g of a flour sample and 4.8 ml of a 2 % sodium chloride solution. The mixing chamber is fitted with a sieve at the base, so that the soluble components, such as the starch and the soluble proteins, are washed out due to the addition of the sodium chloride solution and the continuing mixing. After the washing process, the remaining wet gluten is centrifuged to remove the superfluous water. The weight of the centrifuged wet gluten is ascertained and multiplied by ten. The result is given in percent of wet gluten.

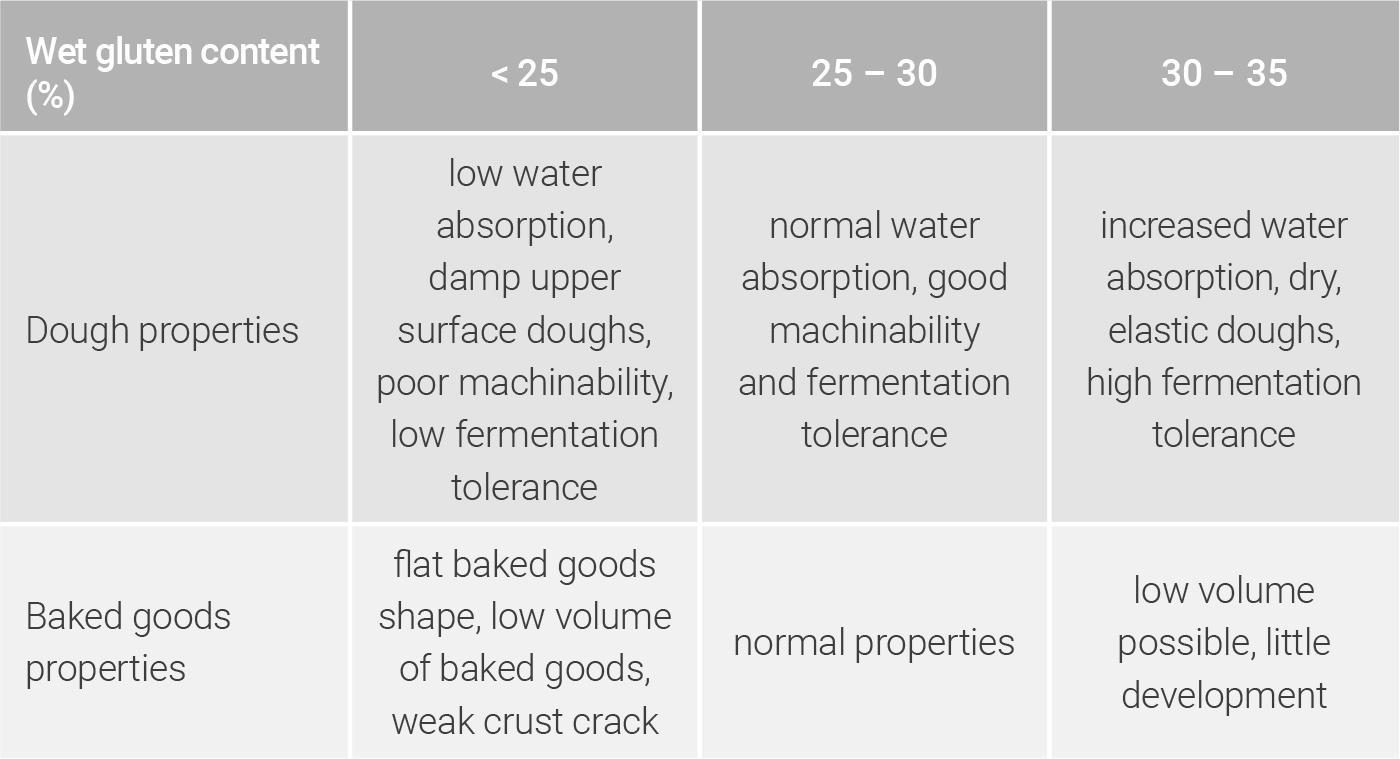

Table 2.11: Dough and baked goods properties depending on the wet gluten content of wheat flour type 550

Over and above the wet gluten, the gluten index can be determined in addition. Here, the washed out wet gluten is put into a special sieve container and subsequently centrifuged. As a result of the centrifugal force, a part of the wet gluten is pressed through the sieve. The stronger the gluten, the more wet gluten remains on the sieve.

The total weight of the gluten corresponds to the wet gluten content. The percentage which is not pressed through the sieve corresponds to the gluten index. Is the gluten very weak and with a flowing capability, a large part will be pressed through the sieve and lower values for the gluten index obtained. In the case of a strong and short gluten, only a small part is pressed through the sieve and high values are obtained for the gluten index.

Over and above the determination of the wet gluten quantity, additional information is obtained on the plastic and elastic properties of the gluten via the gluten index.