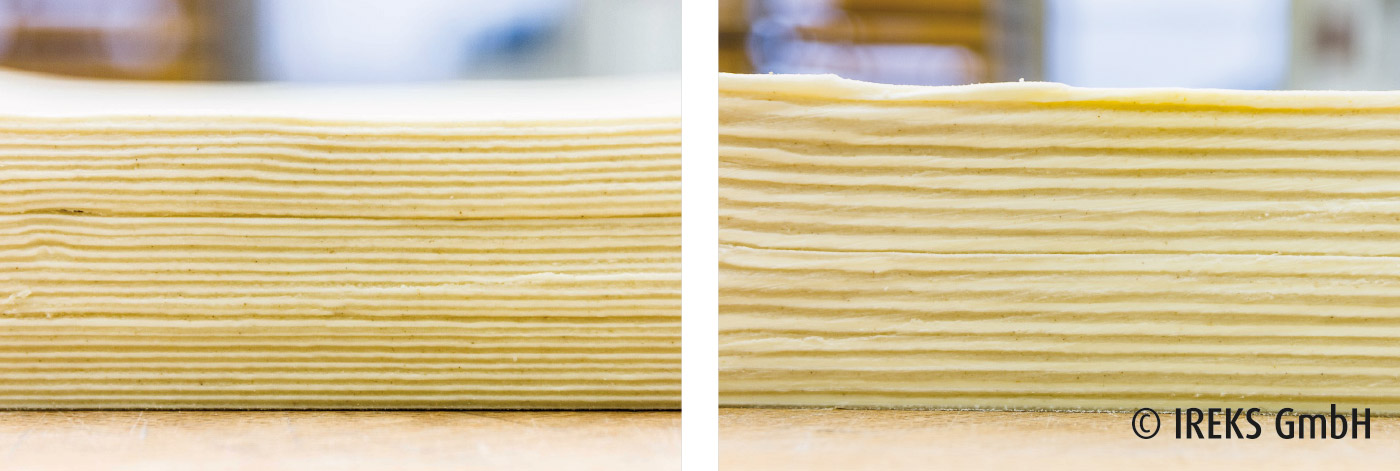

Working the fat layers into the dough takes place by putting the fat in the dough and subsequently folding and rolling out several times.

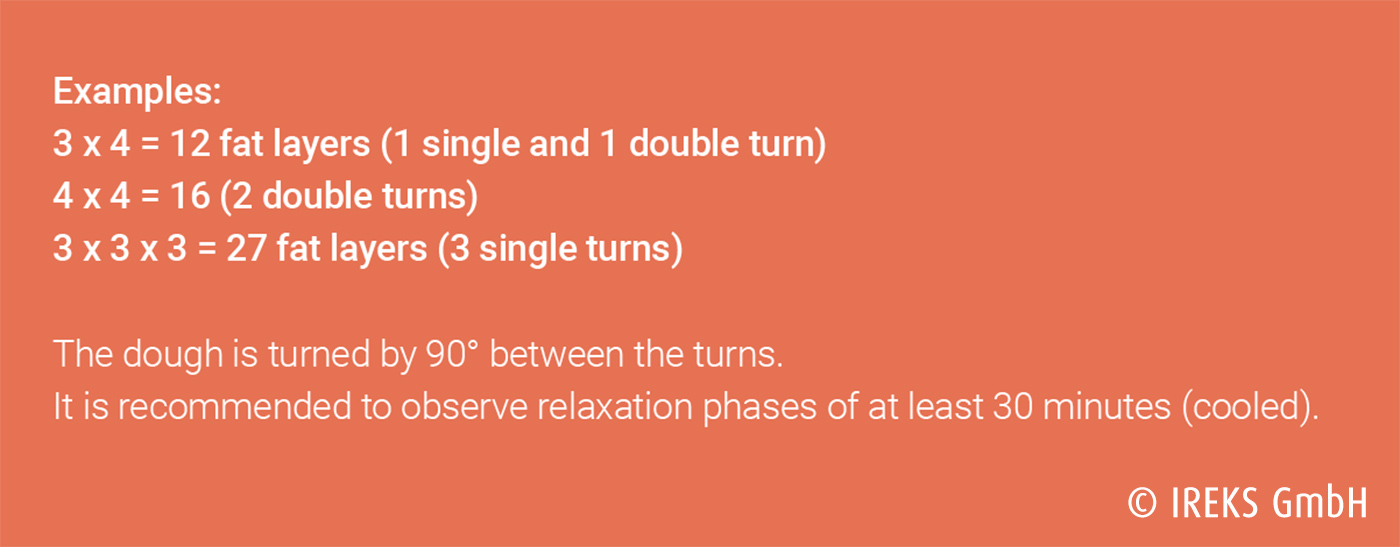

In this way, the number of dough layers/fat layers is multiplied. This procedure is called folding, if the dough layering/fat layering takes place in stages by rolling out and by placing the dough portions on top of one another. In this craft processing, the dough is rolled out with the folded-in fat to a thickness of 10 mm on the dough sheeter and folded in a single or double turn.

Bulk fermentation then takes place in the refrigerator or in the freezing chamber. For further processing, the dough is turned by 90° and rolled into a dough sheet again. By folding the dough sheet once more, giving a single or a double turn, the fat layers in the dough are multiplied. The folded dough is allowed another relaxation phase in the refrigerator before rolling out and folding takes place again. Once the required number of fat layers for the corresponding type of baked goods and amount of fat has been achieved, the dough is cooled once more before further processing. For optimum results, very careful and exact working is required.