Storage temperature

Recrystallization takes place fastest in the temperature area of around 0° C. By means of freezing or storage at high temperatures, this can be delayed. Warm storage is almost never used in practice, however, as temperatures above 55° C and air humidity levels of

approx. 80 % would have to be used (cf. Klingler 1995). Over and above, a high energy input is required and the danger of microbial deterioration exists. Freezing pre-baked and finished baked goods at -18° C has become established as a measure.

Dough method/Recipe

To delay the drying out of the baked goods, it is meaningful to work with high dough yields to increase the water content of the crumb. By the use of sponges, the flour components have more time to swell and enzymatic decomposition processes of the starch components occur, whereby the freshkeeping is improved.

Baking process

To obtain baked goods which are as moist as possible with a good freshkeeping, initial baking should take place at high temperatures and baking finished with a dropping heat. Shorter baking times at high temperatures lead to a higher water content in the crumb than long baking times at lower temperatures.

Improvers/Mixes

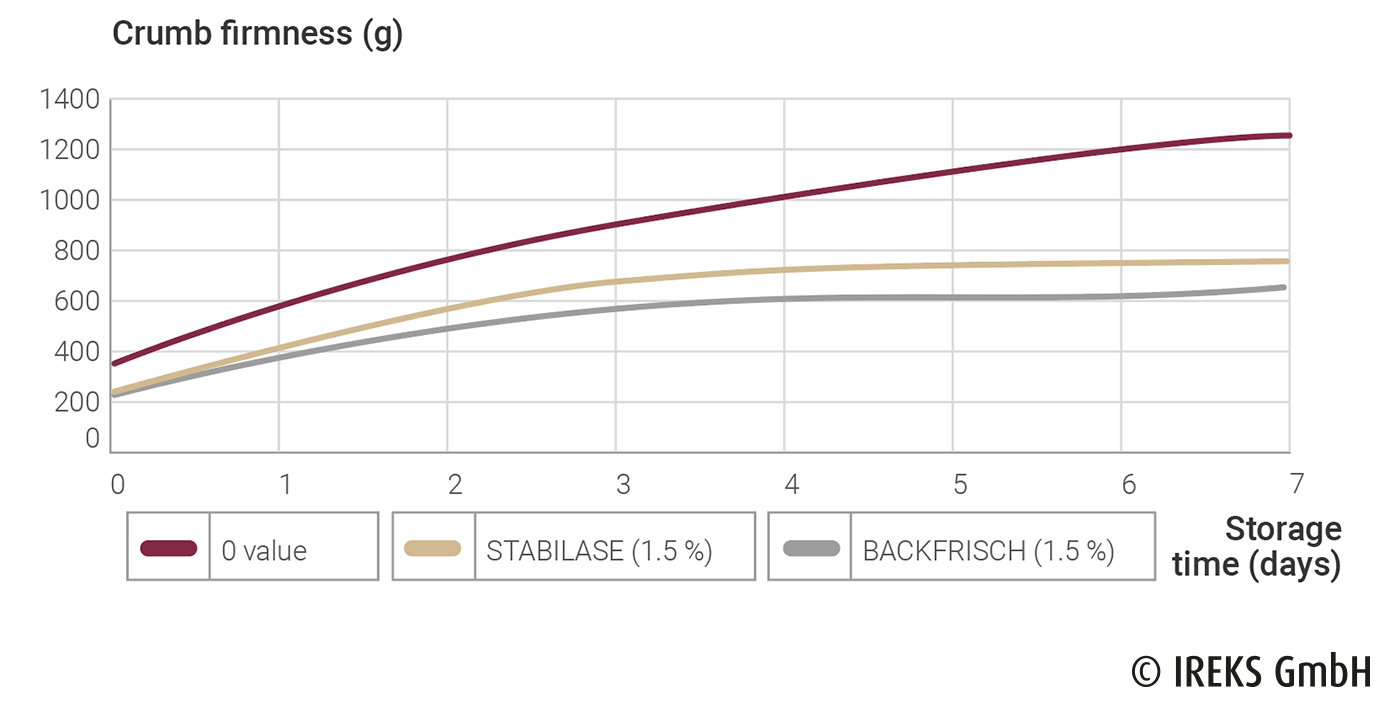

Improvers such as BACKFRISCH or STABILASE contain enzymes which split a part of the starch during gelatinization in the baking process into smaller pieces. This influences the retrogradation, as fewer hydrogen bonds are formed during the ageing of the bread. In

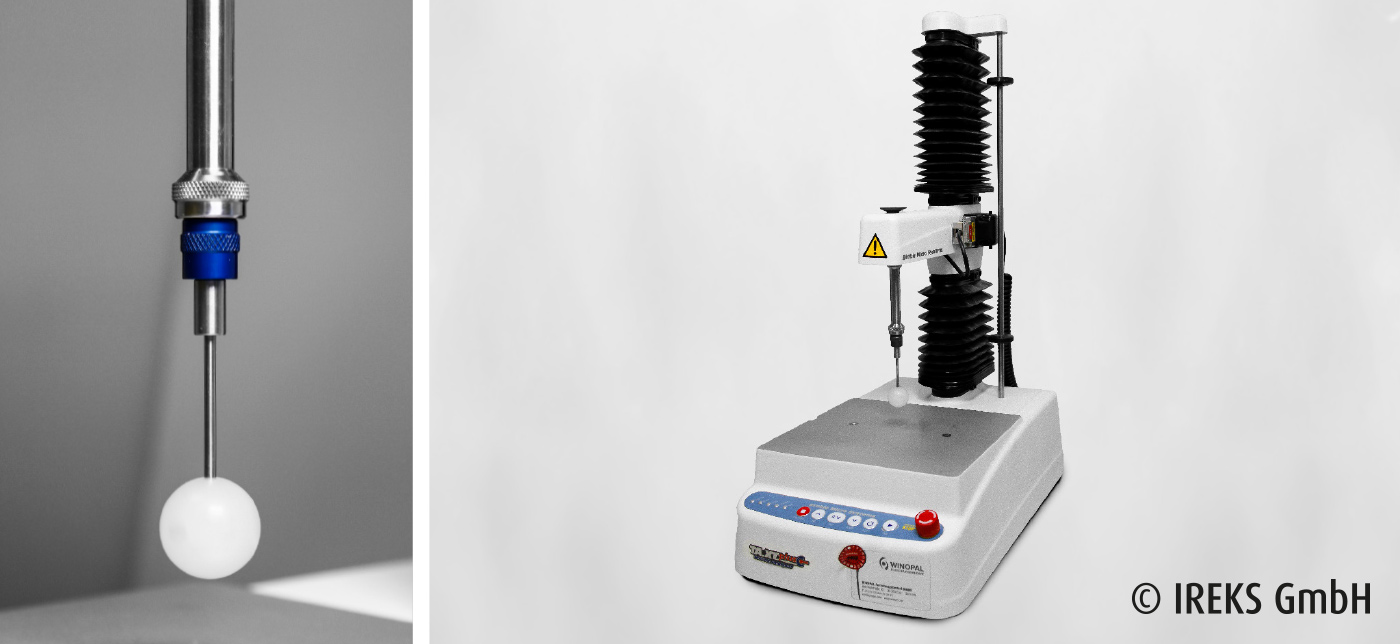

addition, BACKFRISCH contains guar gum and an emulsifier (E 471). The guar gum provides a higher water absorption of the doughs and, in this way, counteracts the drying out. Due to inclusion in the starch matrix, the emulsifier delays the retrogradation. As a result, the crumb remains longer soft and fresh. Freshkeeping in the form of the firming of the crumb depending on the storage time can be examined very well with the help of a texture analysis.

In illustration 16.4, the course of the firming of the crumb in mixed grain bread with the use of STABILASE and BACKFRISCH compared to a zero value without the addition of improver is shown.