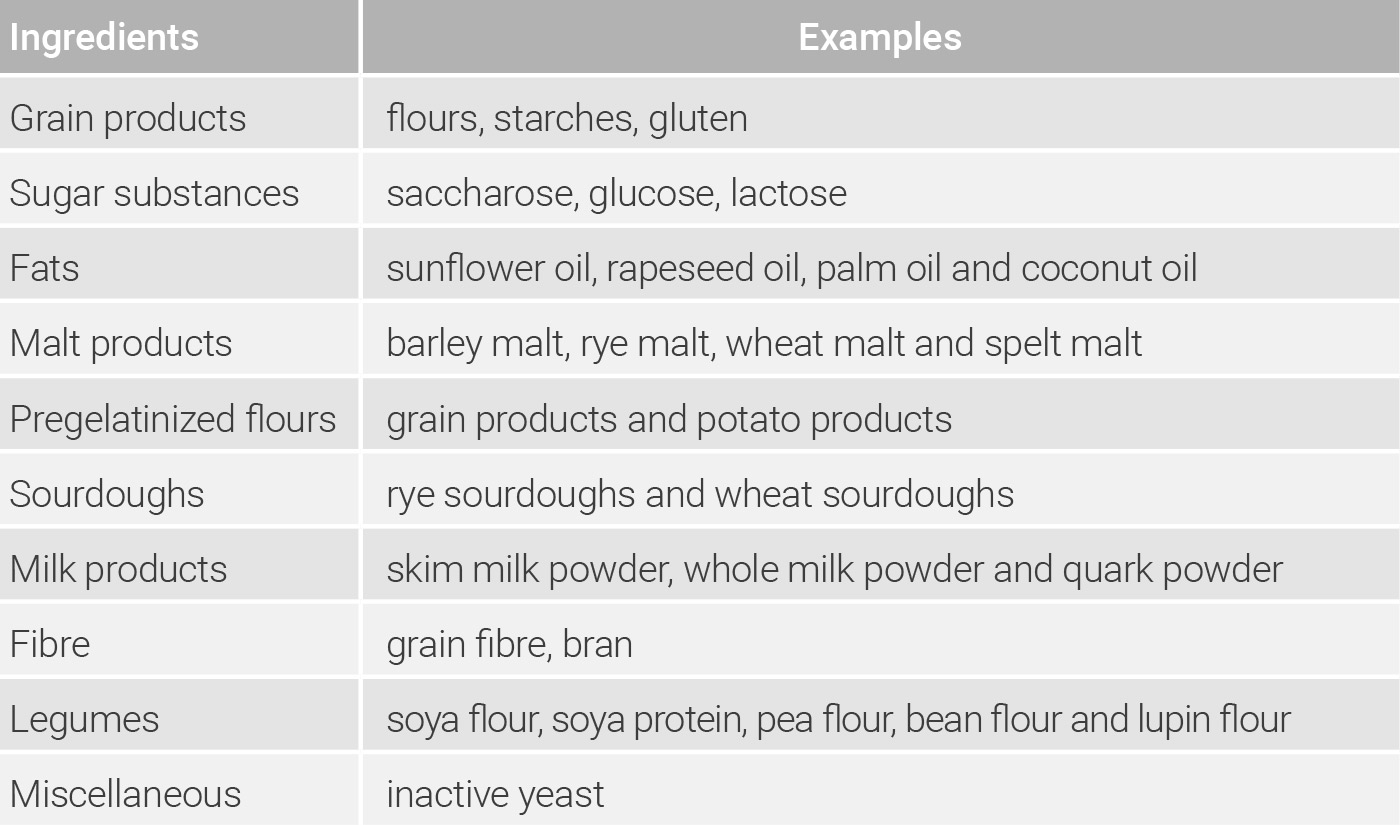

Depending on their area of application, improvers can be put together in different ways from a great number of ingredients. Basically, the ingredients used can be subdivided into ingredients and additives. In table 3.1, individual ingredients and examples are given which are then described with their effect (cf. Backmittelinstitut e.V. 1999).

Grain products

Grain products form the basis for the manufacture of improvers and mixes. Here, all common varieties of grain, such as wheat, spelt, rye, barley and oats, etc., are used. Over and above, individual fractions, such as starch or gluten, can also be applied to achieve special properties in the baked goods. The fermentation tolerance and the gas retention property of the dough pieces are enhanced by means of gluten, whereby a higher volume of baked goods is obtained.

Sugar substances

Sugar substances have a great influence on the taste of the baked goods. What is more, sugar substances fulfil important technological properties and can influence the yeast activity, freshkeeping, colouring behaviour and crust and crumb texture considerably.

Fats

Fats provide a woolly and relaxed gluten structure in the dough, enhance the machinability and cause a tender crumb texture and good freshkeeping in the baked goods. Moreover, fats can be used in improvers to reduce dust.

Malt products

Malt products are used in the form of malt flours and malt extracts in the manufacture of improvers. In the dough, the sugar substances contained and enzymes of the malts take care of an optimum development. Crust colouring and taste are characterized considerably by the use of malt products.

Pregelatinized flours

Pregelatinized flours are made from grain and potatoes. In this case, the flours are pregelatinized with water and gelatinized using thermic treatment. Subsequently, these are milled, sieved and screened. By the use of pregelatinized flours, the water absorption and the viscosity of the dough are regulated, which contributes to an increase in the water binding and an improved machinability. Over and above, the freshkeeping and the digestibility of the baked goods are improved during the baking process by the release of water to the gelatinizing starch.

Sourdoughs

Sourdoughs mainly consist of bread grain products, water and micro-organisms (lactic acid bacteria). An acidification can be triggered spontaneously by micro-organisms inherent to the flour. As a rule, lactic acid bacteria or a starter (mature sourdough) are used to guarantee an optimum acidification. Sourdoughs are given a keeping quality through stabilization by their own acids or by drying. By the use of sourdoughs, the taste, the crust colouring and the crumb texture are enhanced.

Milk products

Milk products are used in various dried forms of processing. In addition to rounding-off the taste and the characterization of a tender and fine crumb texture, the lactose (milk sugar) is available for an intensified colouring reaction, as it cannot be fermented by the yeast.

Fibre

Due to the high water binding during dough preparation, fibre takes care of an increase in the dough yield and a balanced water content in the baked goods. What is more, fibre has valuable nutrition physiological properties which raise the nutritional value of the baked goods.

Legumes

Legumes are used to optimize the dough texture. Furthermore, legumes influence the colouring behaviour of baked goods.

Example: soya flour

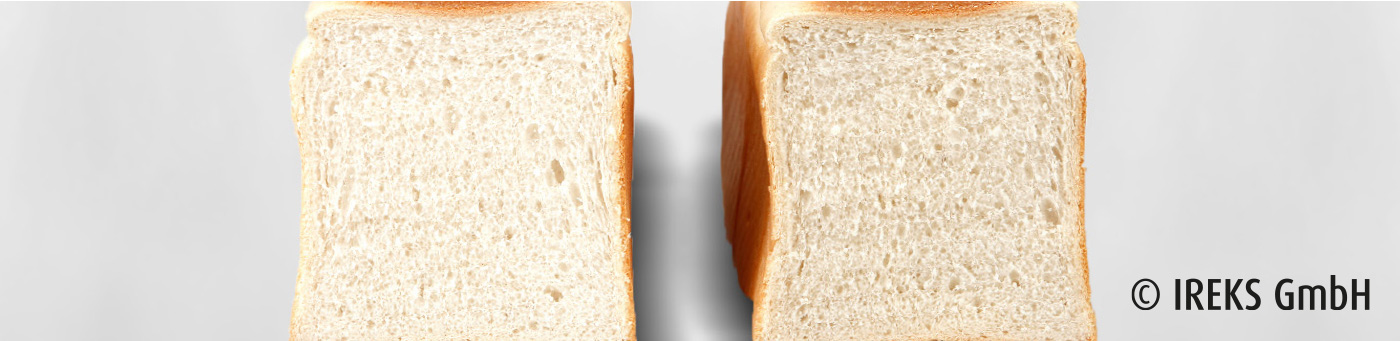

Soya flour has an emulsifying effect and is used in improvers to optimize the dough yield and the machinability. In addition, the gluten is strengthened, contributing to the enhancement of the dough stability. A finer crumb texture and an enhanced crumb elasticity is obtained in the baked goods. The enzyme lipoxidase contained contributes, by means of the oxidation of the carotenoids inherent to the flour, towards lightening the crumb.