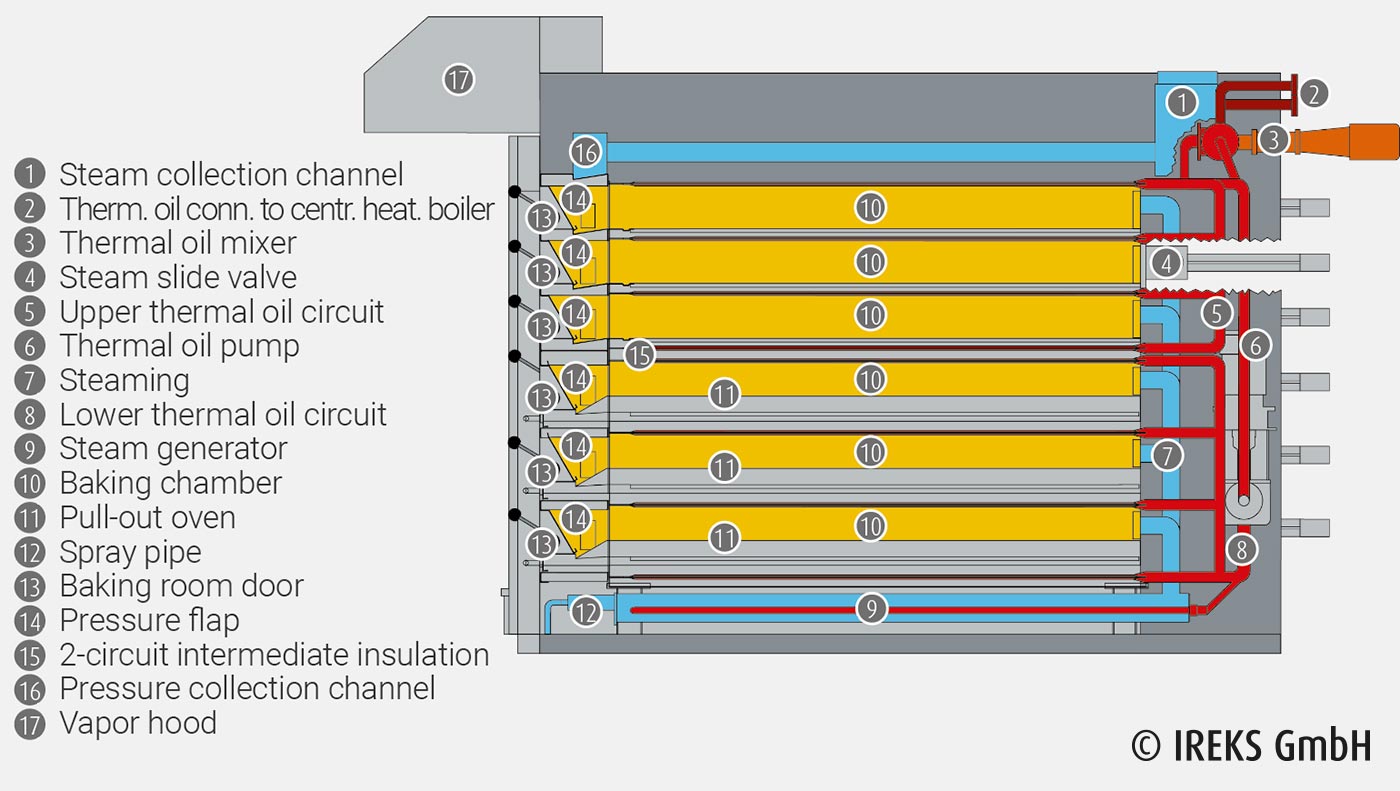

In the case of thermal oil ovens, special mineral oil is used for heat transfer which is heated to 320° C in a boiler hub and then transported via pipes to the radiators. Here, a boiler hub can supply several ovens at the same time. Oil, gas and, in rare cases, electricity are used as sources of heating.

Thermal oil ovens are characterized by a uniform and “mild” transfer of heat. Also in the case of a very low capacity load of the oven, no-overheating takes place. The good heat storage capability of the thermal oil ensures that the oven loses practically no temperature during loading. This can also be of a disadvantage should lots of products with different temperature curves be baked, as it takes comparatively long for a drop in temperature in the oven to take place. For this reason, thermal oil ovens are mostly suitable for baking products which require the same baking temperature. Thermal oil ovens are available as different models such as trolley ovens, deck ovens or tunnel ovens.

In the baking chamber of a trolley oven heated by thermal oil, several radiators are located through which the thermal oil flows. If a trolley with trays is rolled into the baking chamber, then the trays are directly above the radiators. Compared to rack ovens, the trolleys do not rotate in the oven and the heat transfer mainly takes place by means of heat radiation. But models also exist with convection which can be switched on in addition. In the case of deck ovens heated by thermal oil, the thermal oil flows through radiators which are located above and below the individual decks.