Convection/Heat convection is the movement of hot air or hot steam around the goods for baking. Here, the air movement is caused by a recirculating fan. Convection is characteristic for rack ovens and convection shop ovens. Also the introduction of hot steam causes a certain movement of air in the baking chamber.

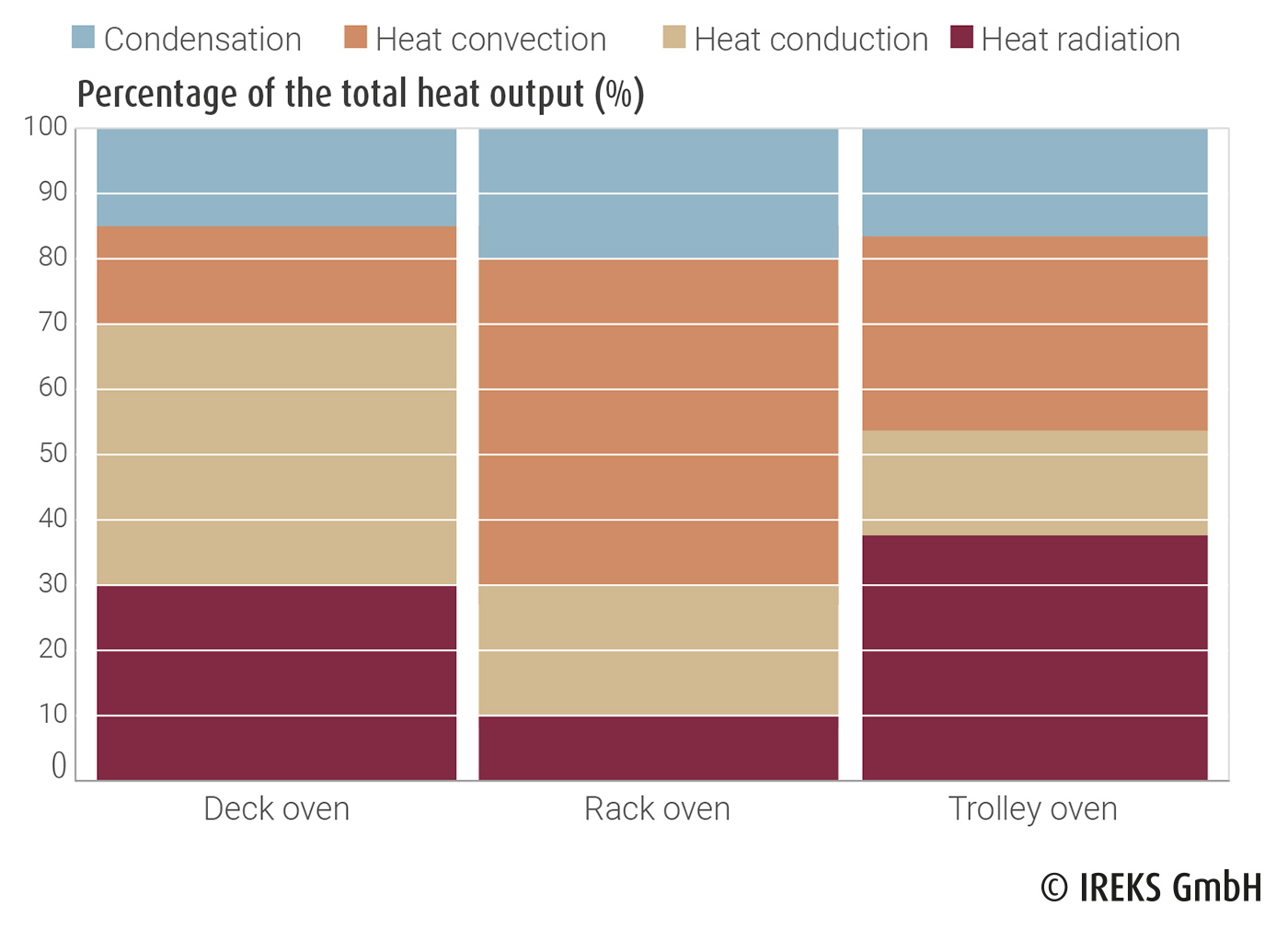

Depending on the oven system used, the types of heat transfer can be distinctly different. While mainly heat radiation is used in the deck oven, heat convection or convection dominates in the rack oven. Trolley ovens is the name for ovens heated by thermal oil into which a trolley is rolled, but does not turn. Several horizontally arranged radiators, through which the thermal oil flows, are found in the trolley oven. The trays of the trolley are directly above the radiators. In addition to convection, the heat radiation above all is responsible for the heat transfer in trolley ovens.