The extensograph is a device for testing the extensibility properties of a wheat dough. Initially, a dough is made in the farinograph which contains 2 % salt, but no yeast. As much water as required is added that the centre of the mixing curve reaches the consistency line at 500 FU after 5 minutes of mixing time. This dough is then shaped long by using the ball homogenizer and the long roller of the extensograph and subsequently allowed to relax in the dough bowl container. Following a bulk fermentation time of 45 minutes, the dough samples are subjected to an extensibility process until the dough sample tears. Thus the extensibility process is recorded and shown as an extensogram. The dough is then shaped long once more and measured again after 90 or 135 minutes.

Evaluation

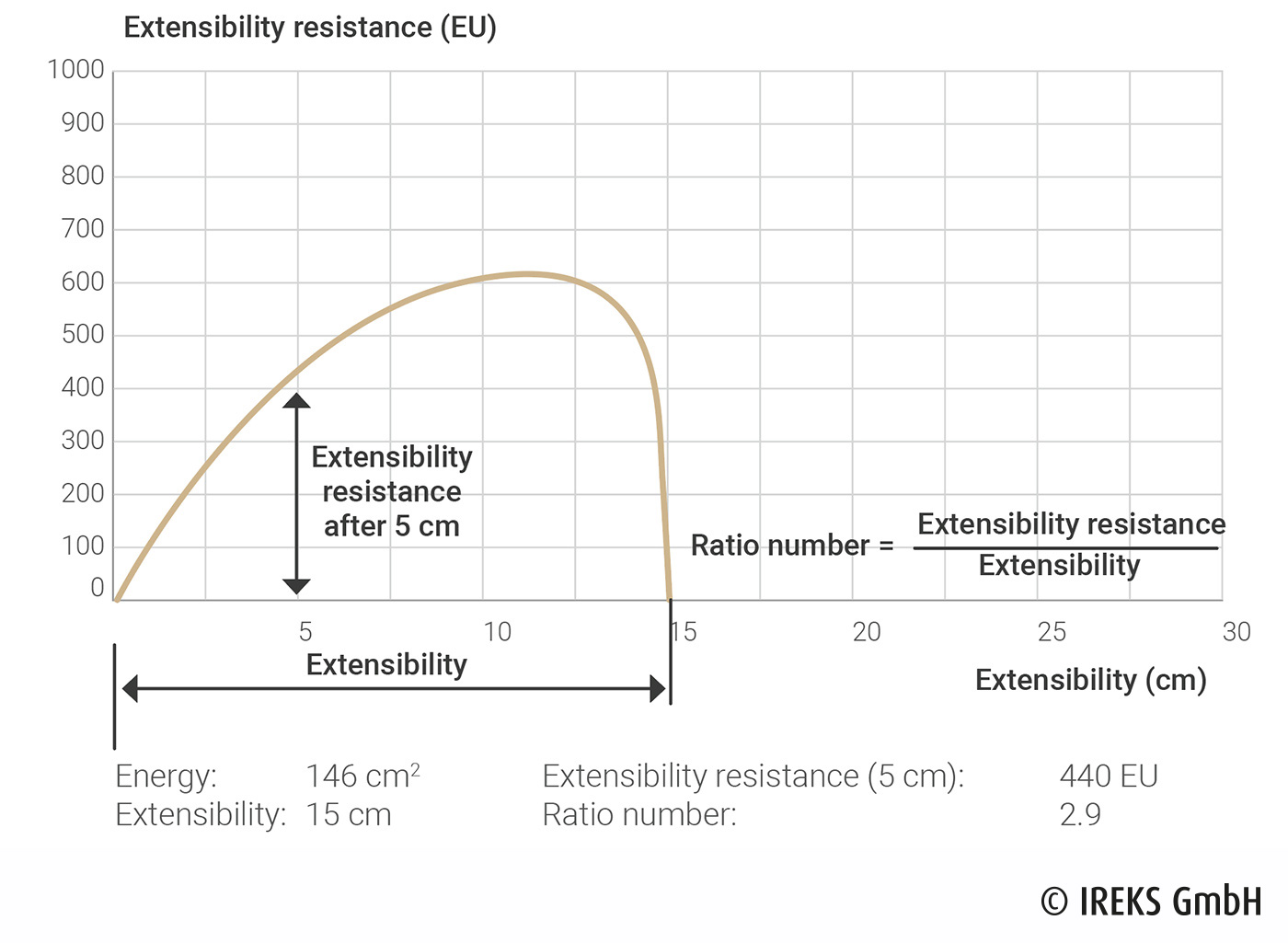

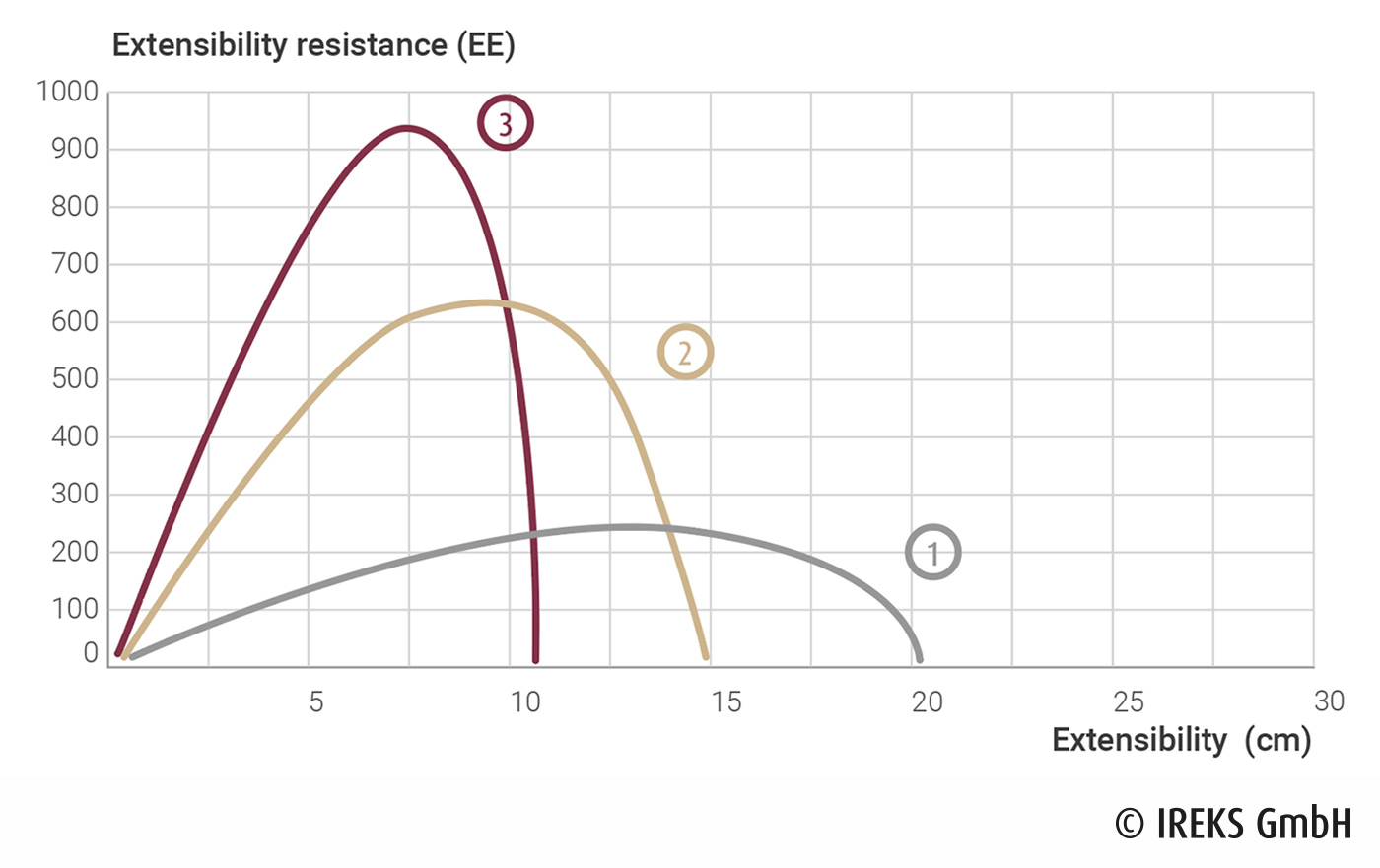

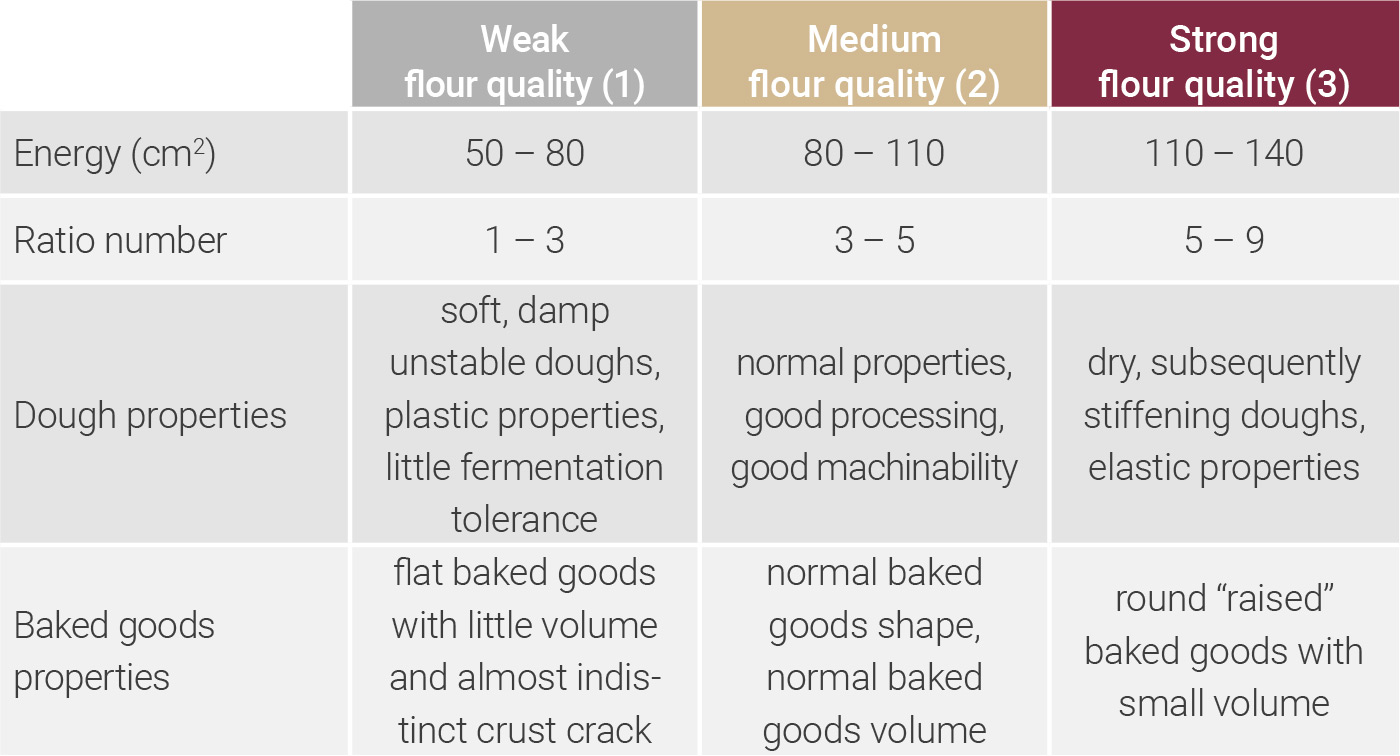

The energy describes the area below the curve of the extensogram and provides information on the expected fermentation tolerance of a dough. High and long curves result in large energy values and characterize doughs with a good fermentation tolerance and a good gas retention property.

The extensibility resistance in extensograph units (EU) describes the elastic properties of a wheat dough. It represents the force which the dough has to find in resistance to the measuring instrument. Doughs with a very large extensibility resistance, but with a small extensibility, are very short and elastic.

The extensibility stands for the plastic properties of a wheat dough. Doughs with a very large extensibility and low extensibility resistance are soft and sticky and have flowing properties.

The ratio number expresses the ratio of the extensibility resistance to the extensibility. Flours with small ratio numbers result in soft, extensible and unstable doughs, whereas flours with large ratio numbers provide subsequently stiffening, elastic doughs.