Wheat flour

For soft baked goods, high-quality wheat flours with a high wet gluten content and a good swelling property and a good extensibility are used. Too low wet gluten contents can be balanced by the addition of wheat gluten.

The amount of gluten and the quality are decisive for the creation of a stable gluten network with many desired small gas bubbles which help the baked goods have the finely-textured structure. Here, to achieve optimum dough properties and the typical baked goods shape, the gluten network is frequently relaxed by intense mixing and by the use of a wheat sponge as well as special improvers.

The enzyme activity and the quality of the starch of the wheat flours used influence the freshkeeping of the baked goods. Flours with high falling numbers and high gelatinization temperatures often lead to dry baked goods.

Sugar (saccharose)

Depending on the type of soft baked goods, there are very different quantities of addition of sugar. The dosages reach from 2 – 3 % in the case of toast bread or sandwich to 30 % and more for brioche baked goods. The sugar promotes the colouring reaction on the crust of the baked goods. In the case of higher additions of sugar, a faster colouring of the baked goods takes place. This results in a shorter baking time and a lower baking loss (example: hamburger buns). In addition, sugar intensifies the baked goods aroma. A further effect comes from the strong hygroscopicity of the sugar. Sugar can permanently bind moistness in the crumb and the crust. If, in addition to saccharose, glucose syrup, invert sugar syrup and, in the case of brioche baked goods, also fructose and/or sorbitol are used, the freshkeeping is also enhanced. In this way, for example, by a partial exchange of saccharose for glucose syrup, the freshkeeping is improved without increasing the crust colouring and the sweetness of the baked goods. Moreover, the aw value of the baked goods is lowered and the susceptibility to mould reduced.

Fats

The use of fats in the production of soft baked goods leads to:

- the enhancement of the freshkeeping properties

- the creation of a more fine-textured crumb

- a short bite

- the formation of a softer crumb texture

- the enhancement of the taste

In the production of soft baked goods, the following fats are used:

Shortening (from “short eating”):

Shortenings are mainly used in countries with an Anglo-American baking culture. These shortenings are hydrogenated and partly hydrogenated vegetable fats with a viscous and soft to plastic and solid texture. They contain a large number of the finest crystals and have a particularly good effect on the dough and the baked goods. The baked goods crumb becomes finer textured and more tender.

Vegetable oil:

For soft baked goods, neutral-tasting vegetable oils are also suitable. The dough properties and the crumb texture are not enhanced to the same extent as is the case with more solid fats, but vegetable oil is nevertheless a good and inexpensive alternative. The quantities of addition should not be more than 10 % based on flour, as vegetable oils tend to cause softer doughs and baked goods with grey crumbs.

Margarine:

Margarines have a positive influence on the dough and baked goods properties. Due to the emulsifiers contained and the percentage of solid fats, margarines show a very good emulsifying effect in comparison to vegetable oil. Margarines provide somewhat more stable doughs, which are less susceptible to temperature and which have a finer baked goods crumb compared to butter or vegetable oil.

Animal fats:

Animal fats, such as lard, suet, fish oil or whale oil, are practically no longer in use today. Although these animal fats have very good technical properties and a neutral taste, they are not put into use.

Butter:

Butter is very popular among consumers and processors. The advantages here are in the smell and taste. When processing butter, lower dough temperatures and lower fermentation temperatures are recommended to prevent the fat melting out.

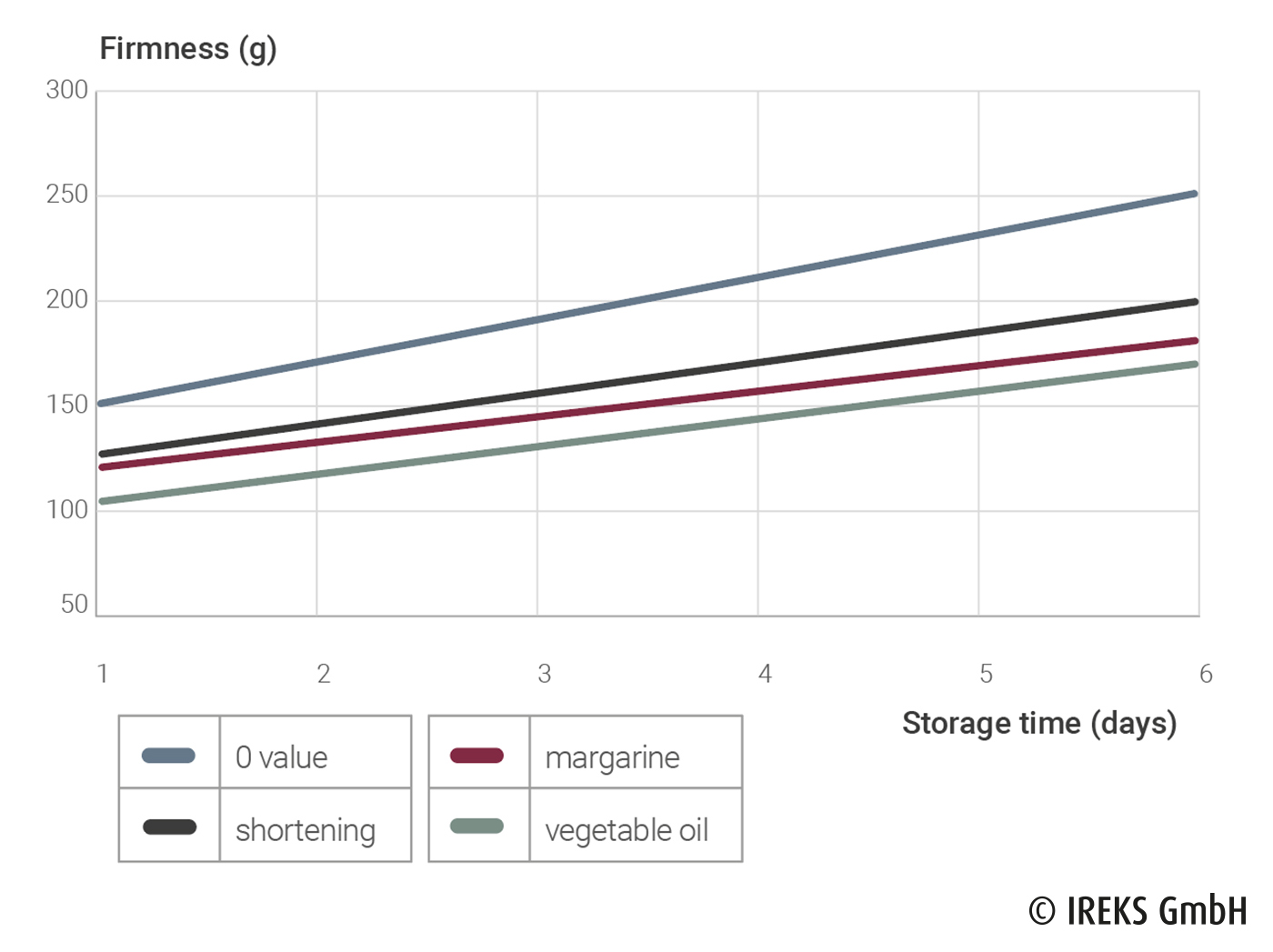

In baking tests (sandwich bread) with 4 % each of margarine, vegetable oil and shortening, the best softkeeping was obtained with vegetable oil during the entire 6-day storage time.

Milk products

For soft baked goods, mostly dry milk products, such as skim milk powder, whey powder or partly whole milk powder, are used. These products influence the colouring behaviour of the soft baked goods, as the milk sugar (lactose) is not fermented by the yeast. But the milk products are also partly used as components of the recipe to increase the value. By the use of milk products, the dough fermentation is slowed somewhat. The texture of the baked goods is finer and more tender, the freshkeeping is improved to a limited extent only.

Yeast

Both dry baking yeast and fresh baking yeast can be used as a baking yeast. The use of liquid yeast is equally possible. The intense raising yeasts or rapid raising yeasts sometimes used for confectionery baked goods, with an increased concentration of sugar, are mostly not necessary for soft baked goods. The higher raising power of these yeasts of up to 30 % is only required in the case of very high concentrations of sugar and short bulk fermentation times. The qualities of yeast available today can be used for all areas of application.

Preservatives

As a result of the good water retention and the long consumption freshness demanded of pre-packed soft baked goods, an addition of preservatives often becomes necessary to prevent the formation of mould. Possible preservatives are sorbic acid (E 200) and potassium sorbate (E 202) as well as propionic acid (E 280) and their sodium, potassium and calcium salts (E 281 – E 283). The relevant maximum limitation levels apply depending on the type of baked goods and the regulations related to the country.