The correct time of mixing depends on numerous factors and has a great influence on the length of production of the baked goods. The following factors have to be adjusted to one another to achieve an optimum quality of baked goods:

- raw material qualities

- mixing system

- mixing speed

- type of dough

- dough size

- dough firmness

- dough temperature

- type of dough method

- precursors

- pre-treatment of the flour

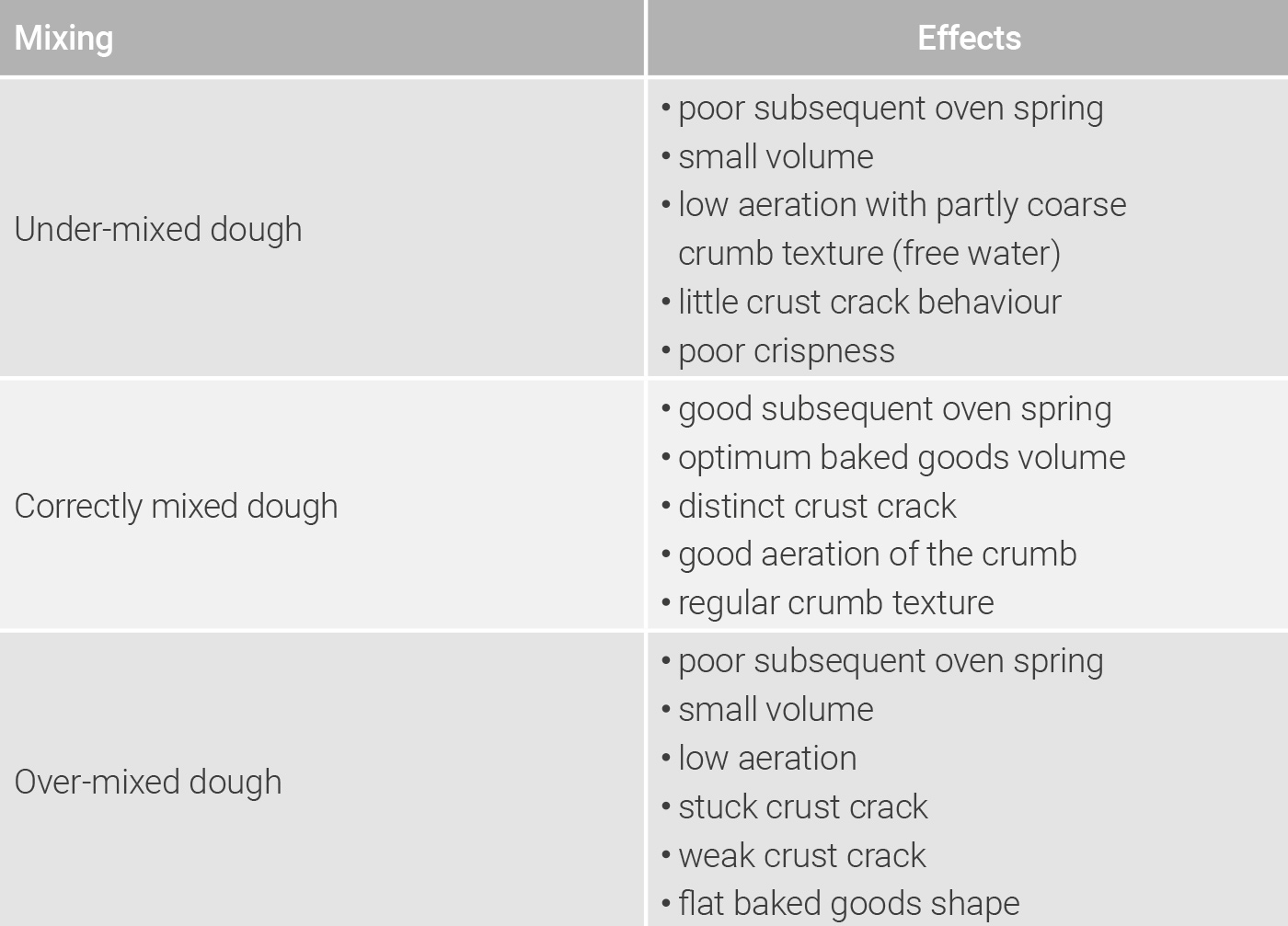

The influences and effects of incorrect mixing on the quality of the baked goods are shown in table 5.14.

Mixing doughs containing rye

Doughs for rye, coarse rye and mixed rye bread with a high percentage of rye are mostly only mixed slowly and less intensely.

Mixing doughs containing wheat

Doughs for wheat morning goods, wheat, mixed wheat and mixed grain bread are mixed intensely, based on the percentage of wheat.

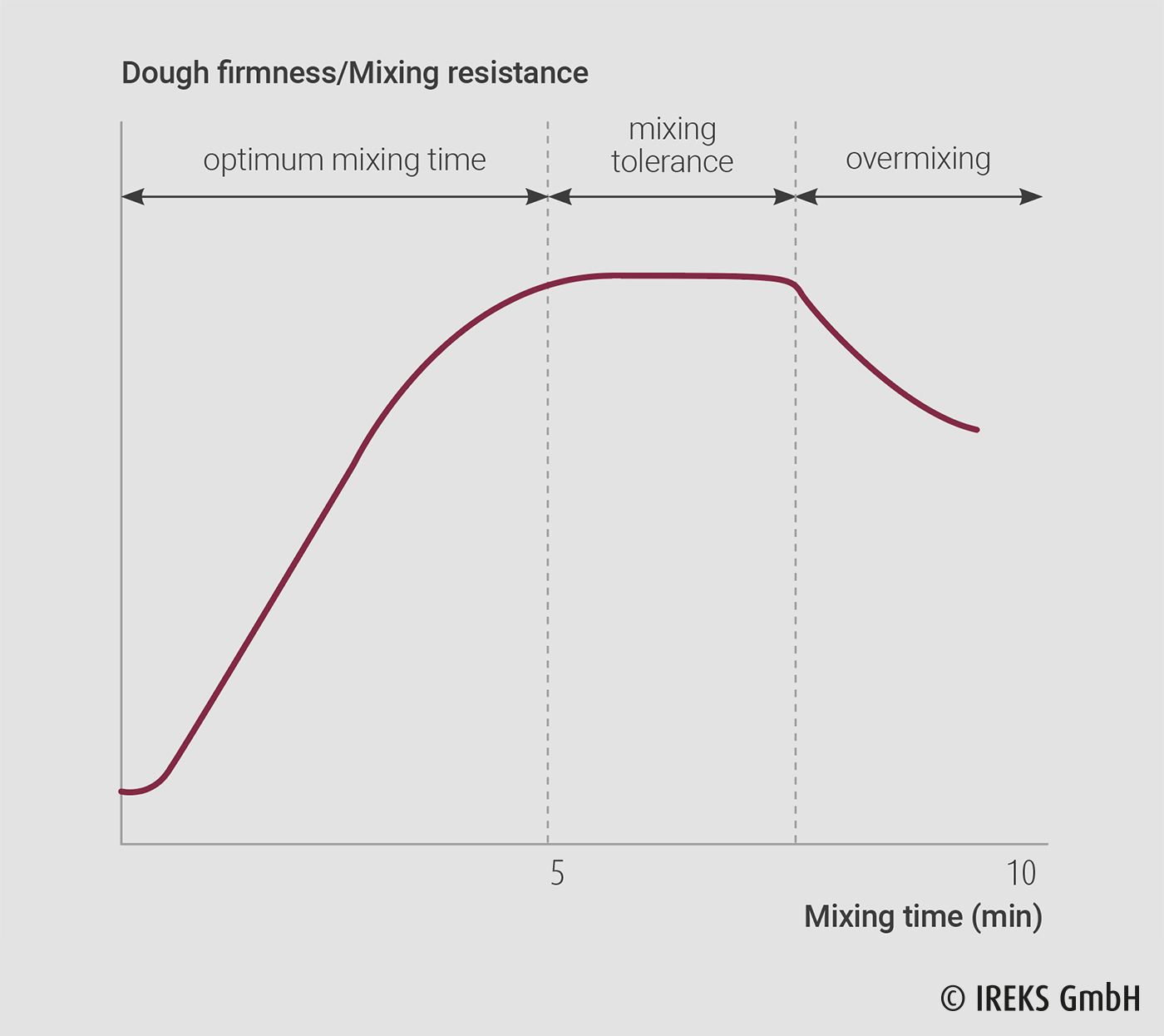

Illustration 5.5 shows the dough firmness depending on the mixing time. Every dough has an individual mixing optimum. The mixing tolerance can, depending on the quality of the raw materials and mixing intensity, have a different length. In the phase of overmixing, the dough becomes softer once again, from which corresponding baked goods faults can result.