The background is the challenge posed to bakeries to have freshly baked products available for sale the whole day long. For reasons within the company, this is often only possible in a limited way or only with losses in quality. The basic idea of the interrupted baking method is the production of pre-baked bread for stockpiling to then finish baking on demand and to be able to react flexibly to demand at the sales point. The process has already been described in the editions of the “Bäckereitechnisches Handbuch” from IREKS since 1965.

Processing parameters

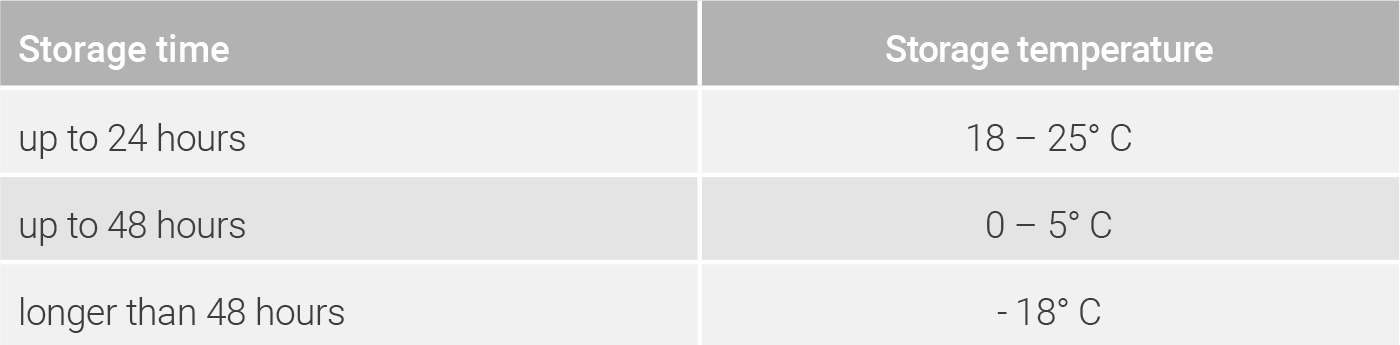

The baking time of the first baking phase is to be chosen in such a way that a core temperature of at least 96° C is obtained. Reaching the core temperature depends on the type of oven, the scaling weight of the dough pieces, the selection of the initial baking temperature and the course of temperature of the baking program. The time which is required to achieve a core temperature of 96° C should be determined empirically for each type of bread. Following the cooling of the bread, packaging takes place in gas-tight foil to prevent drying. The wrapped bread can then be stored with the following parameters.

Table 13.2: Storage times after the first baking phase of the interrupted baking method depending on the storage temperature

Some manufacturers of cold dough technology offer climatic chambers for cool storage of the pre-baked products. In these special climatic chambers, a high air humidity is set to protect the bread against drying. In this case, wrapping the bread can be omitted. Over and above the setting of the low temperature and the high air humidity, these chambers have UV lamps to delay the growth of mould fungi and thus to increase the storage time of the bread.

The maximum storage time after the first baking phase depends on a great number of parameters. Mould contamination and other bread diseases have definitely to be ruled out. The process of cooling the bread after the first baking phase is especially critical. A contamination with mould spores from the air has to be counteracted here by means of appropriate measures. The bread should cool in clean, draught-free rooms which are cleaned regularly and where no other goods or raw materials are stored.

The time of the second baking phase is also in line with the core temperature, which should be at least 96° C. For a rapid heat transfer, a generous addition of steam is recommended.